Incorporating EEASY Lid into Packaging Production Lines: Applying Decades of Industry Expertise

Packaging production lines can involve a lot of complexity. From cappers to pasteurization tunnels, cooling tunnels, dud detectors, labelers and palletizers – there are many steps to getting a product packaged. Most of us don’t think about this process, but at CCT, we are always thinking about ways to help food manufacturers and fillers adapt their packaging lines to accommodate the EEASY Lid.

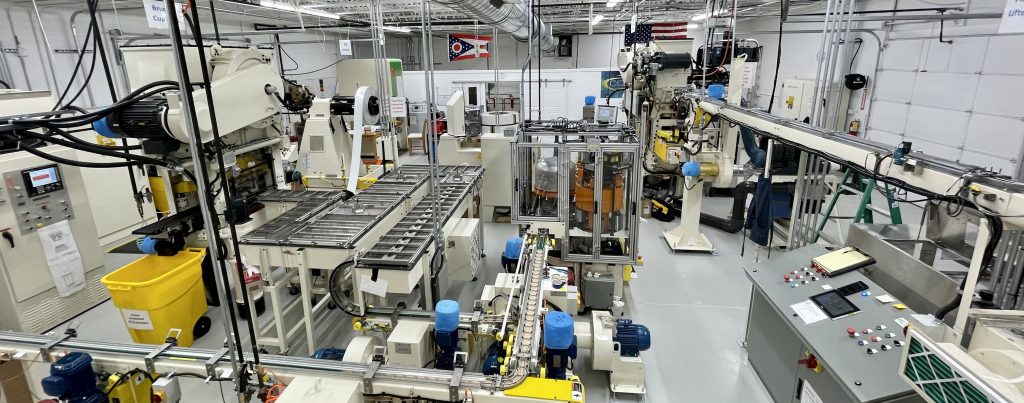

While every packaging production line is different, CCT’s worldwide technicians, Norm Brown and Terry Ryan (who come with a combined 70+ years of packaging industry experience), have the expertise to analyze each line set up to determine what adjustments and tweaks need to be made to incorporate the EEASY Lid.

For example, packaging production lines vary based on how each line approaches handling and capping. That’s where our team looks at what cap delivery systems are available and adaptable that can seamlessly be incorporated into the packaging production line to accommodate the EEASY Lid.

The team can also assess what tweaks and adjustments need to be made to existing equipment to ensure that incorporating the EEASY Lid in the production line process goes off without a hitch. An example of such a tweak might include repositioning Air Knife Blower nozzles so that the air blown removes all of the moisture off the lids, and so that the nozzles themselves do not hit the lid.

When it comes to packaging production lines, it is a certainty that one size solutions don’t fit all. CCT recognizes that each packaging production line is different, and there could be a number of ways to adapt a line to run the EEASY Lid. Our team of experts is ready to conduct a diagnostic assessment of your packaging production line to determine the best approach for integrating the EEASY Lid.