Aluminum Packaging Solutions: The Circular Economy in Action

Our current linear economy of take-make-waste in production and consumption is threatening the health of our planet. Climate change and biodiversity loss are the damaging fallout from this resource intensive way of life. Turning this around will take a concerted, collaborative effort to transition to a circular economy.

Aluminum is one material that can play a key role in moving toward a resource-efficient, circular economy.

A circular economy keeps products and materials in use for as long as possible and regenerates natural systems. Making the shift to a circular economy is critical to reducing the 45% of harmful emissions that are generated from the way we make and use products and food and mitigating the more than 90% of biodiversity loss resulting from the extraction and processing of natural resources.

According to the Ellen MacArthur Foundation, an organization dedicated to speeding up the transition to a circular economy, “we must transform every element of our take-make-waste system: how we manage resources, how we make and use products, and what we do with the materials afterwards. Only then can we create a thriving circular economy that can benefit everyone within the limits of our planet.”

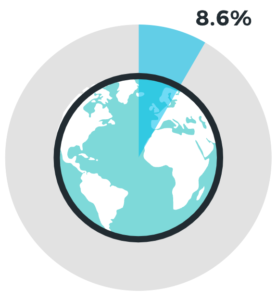

Source: Circularity Gap Report

We have a long way to go to successfully make the shift to a circular economy. According to the Circularity Gap Report, over the last six years the global economy consumed over half a trillion tons of virgin materials and only 8.6% of these materials made it back into our economy, leaving a massive circularity gap of over 91%. Closing that gap will require using more sustainable, circular materials.

Aluminum, which can be recycled over and over again without losing its quality, is a low carbon resource that supports a circular economy. Manufacturing with recycled aluminum uses 95% less energy than using bauxite ore, the raw material aluminum is made from.

Findings from recent research examining the recycling of three beverage container materials – aluminum, glass and plastic (polyethylene terephthalate – PET) also show that aluminum best supports a circular economy. Commissioned by the International Aluminum Institute (IAI), the study found that more than 70% of the material used in aluminum cans is recycled into new products – almost double that of glass (34%) and plastic (40%).

Consumers are increasingly becoming knowledgeable about the circular economy and their attitude towards it is generally positive, according to a survey by DNV. This knowledge is translating to more active participation in the circular economy, with more than 48% of survey respondents saying they buy products with recycled properties.

Transforming how resources are used is critical to building a circular economy. Manufacturers can play a key role in making our economy more circular, reducing the climate impact of their products by maximizing the use of recyclable materials in packaging.

At CCT, we take a circular approach to packaging with the EEASY Lid – the world’s first aluminum lug lid. Durable, light and climate efficient, the EEASY Lid is easy to use and open and highly effective in keeping jarred products safe and fresh. The EEASY Lid is the consumer and climate friendly packaging solution manufacturers need to reduce their carbon footprint and drive the circular economy forward.