Behind the Scenes: A Look at How CCT is Optimizing Production Line Efficiency

CCT’s 16,000 square foot, state-of-the-art technology center located in Dayton, Ohio, is a hub of activity, with a production line capable of producing 800 aluminum lug EEASY Lids per minute – more than 250 million annually.

To meet rising demand for the EEASY Lid, we recently made improvements to our production line, optimizing the manufacturing process to increase efficiency.

Here’s a quick overview of how we achieved that and some photos of the production line in action.

Optimizing the efficiency of our production line starts with our control engineer who automates production line processes to drive productivity, quality, and safety.

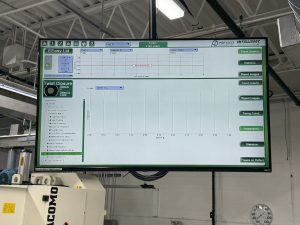

We recently added display screens in key locations on the work floor to allow for real-time monitoring of manufacturing processes which helps operators quickly see, identify, and address any production line issues that may arise.

Production line efficiency is further optimized by scroll cutting strips of aluminum to reduce material waste. These strips are fed into a new cup press, which increases the speed and proficiency of forming the EEASY Lids, ensuring the consistent shape and quality of each lid.

A proprietary EEASY lid mobile tester is also increasing production line efficiency, saving time and labor. The mobile tester performs quality control checks of the innovative EEASY Lid technology formed on the lid and is one of the final inspection points before the lids are packed and shipped out on their way to making jar lids easier to open for everyone.

Our production line is running at peak efficiency and is ready to make your packaging more accessible and sustainable.

Contact us today to learn more about the EEASY Lid – the only jar lid that truly optimizes the jar opening experience for everyone.