Behind the Scenes: A Photo Tour of CCT’s State-of the-Art Technology Center

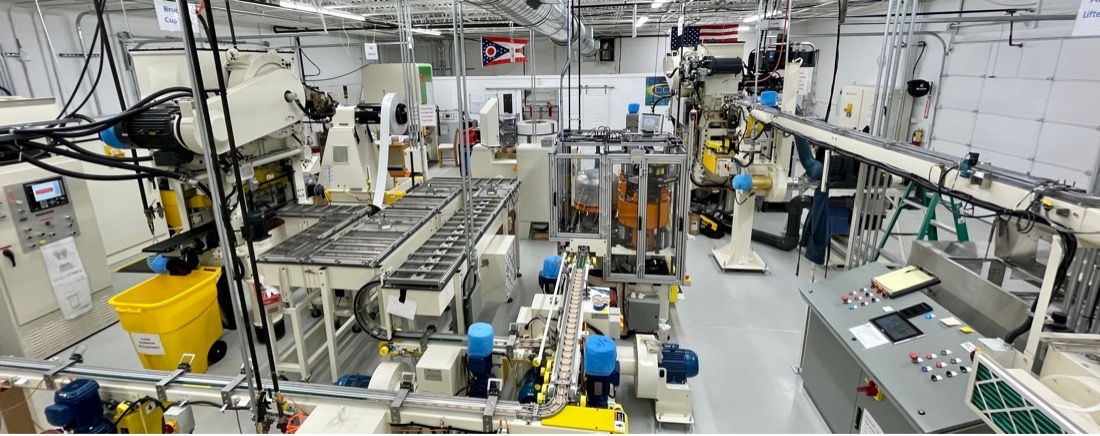

CCT’s state-of-the-art technology center, located at our headquarters in Dayton, Ohio, is where we manufacture the software designed EEASY Lid. The 16,000 square-foot facility houses custom machinery designed to produce the CT and aluminum lug versions of the EEASY Lid.

Each machine in CCT’s production line performs a specific task that builds a component of the EEASY Lid as it moves down the line. When the process is complete, the finished product is the most innovative, easy-to-open jar lid on the market.

CCT’s production line has the capacity to produce about 800 aluminum lug EEASY Lids per minute – more than 250 million annually.

Before embarking on a photo tour of our technology center, we thought it would be helpful to give a brief rundown of what each machine does in the production of the EEASY Lid:

Uncoiler – This is a material handling machine at the beginning of the production line used to hold and safely uncoil the aluminum coil strip. The machine controls the speed and direction of the metal as it moves to the next step of the manufacturing process.

Cupper Press – The cupper press begins to form the jar lid with a die set that presses the aluminum into a uniform lid shape.

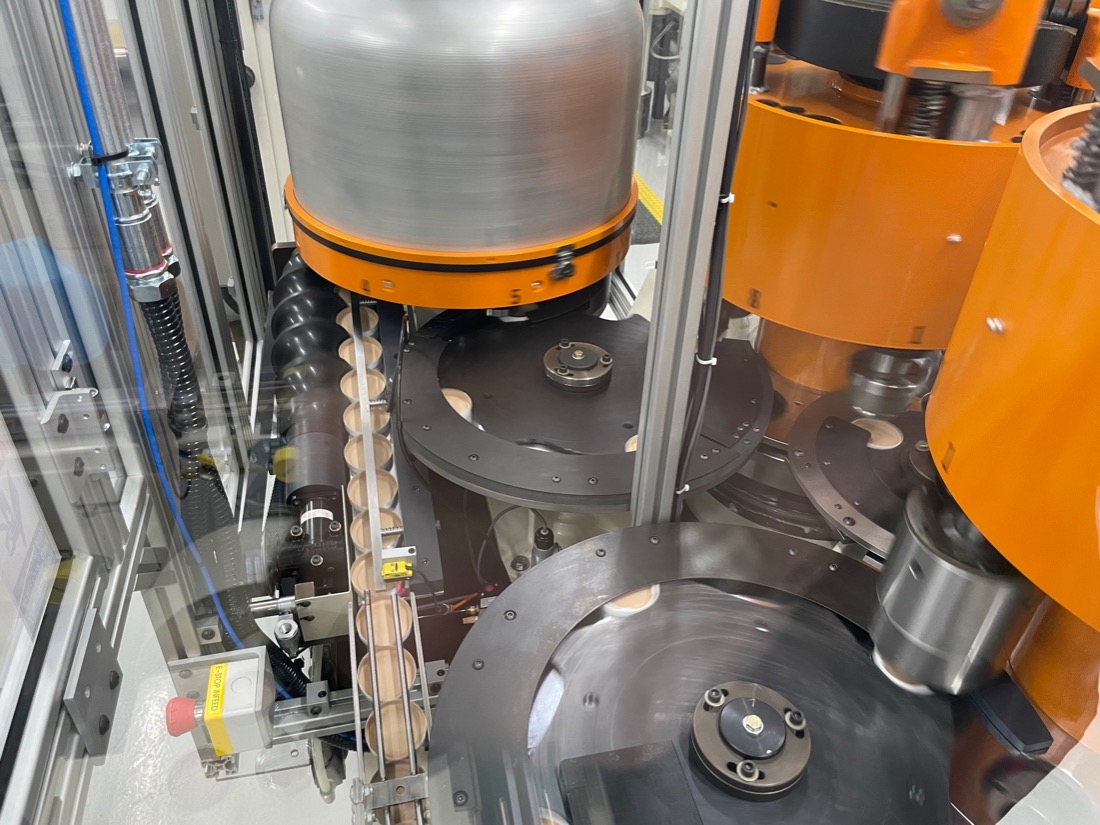

Lugger Machine – This machine forms the lugs – equally spaced tabs – that are positioned on the inside of the lid’s skirt (the part that comes down around the mouth of a jar). These lugs are designed to grip the threads of the jar, allowing the lid to twist into place.

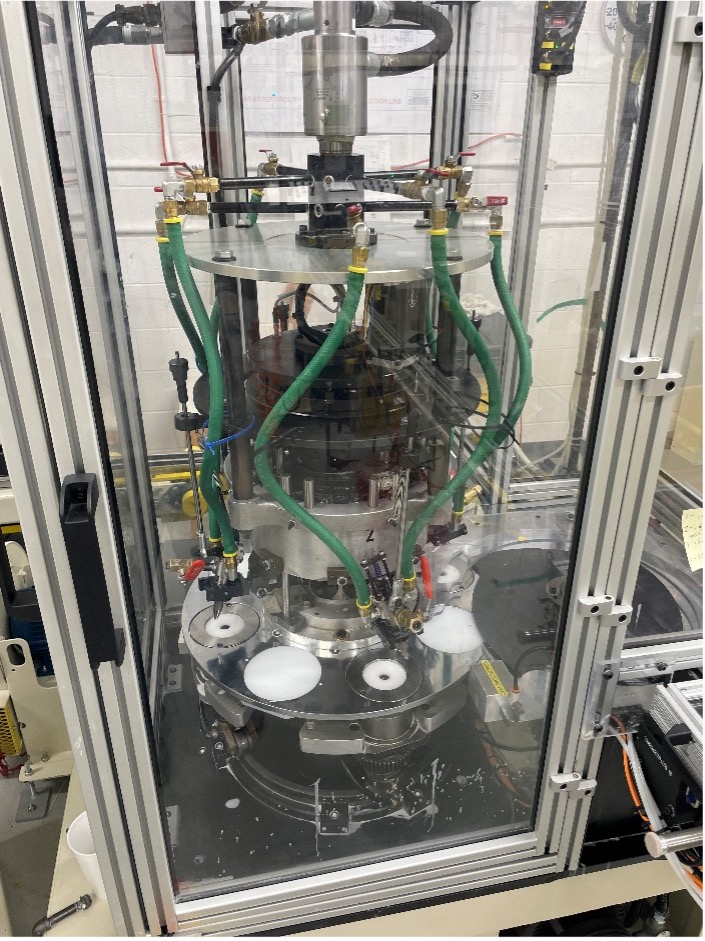

Plastisol Liner – The function of this machine is to heat the plastisol liner and apply it to the underside of the jar lid. Plastisol is a common, FDA approved liner frequently used on closures for jars containing vacuum-packed food items to hermetically seal the lid to the jar.

Oven – Once the lids have had the plastisol applied around the perimeter of the inside, the lid will travel through the temperature-controlled oven to properly bake and cure the plastisol within the lid.

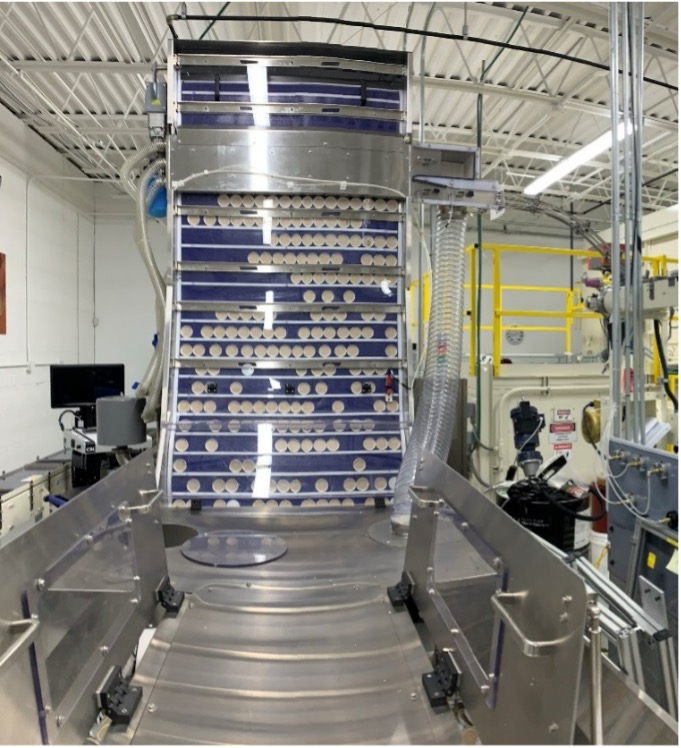

Hopper – A hopper is a large rectangular shaped device that accumulates and stores the jar lids until they are ready to be transferred to the conversion press.

Conversion Press – The conversion press stamps the software designed EEASY Lid technology onto the lid and is inspected one last time before a controlled number of lids are placed into boxes for shipping.

Without further ado, here’s a behind the scenes look at how the EEASY Lid is manufactured.

1. Coils are placed on the uncoiler

2. Standing at the controls for the uncoiler

3. Aluminum coils are on the uncoiler, and coil feeds into the cupper press

4. The cupper press stamps out cupped lids from the aluminum foil

5. Lugger machine adds the four lugs to the lid

6. Lids leave the lugger machine and travel on conveyor over to the plastisol liner

7. Far Left: Coil on the uncoiler feeds into the cupper press

Front Center: Lids leave the lugger machine and travel on conveyor over to the plastisol liner

Far Right: Lids exit hopper via conveyor belt and are transferred to the conversion press

8. Lids enter the plastisol liner applicator to have the plastisol placed around the perimeter of the interior wall of the lid

9. Lids go into the oven from the plastisol liner

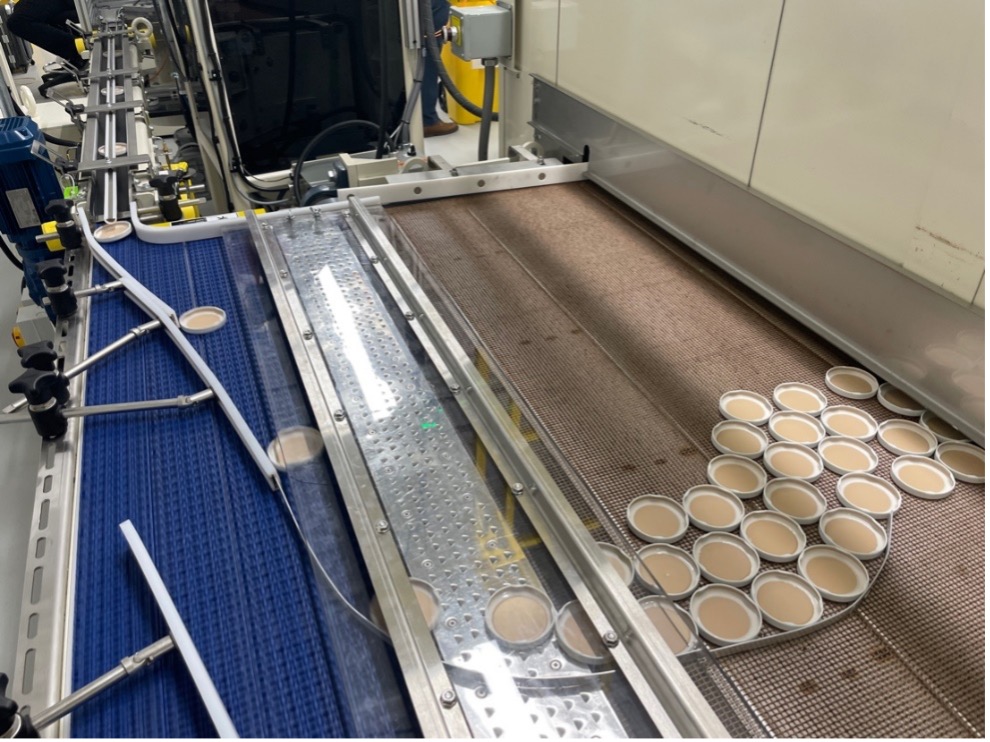

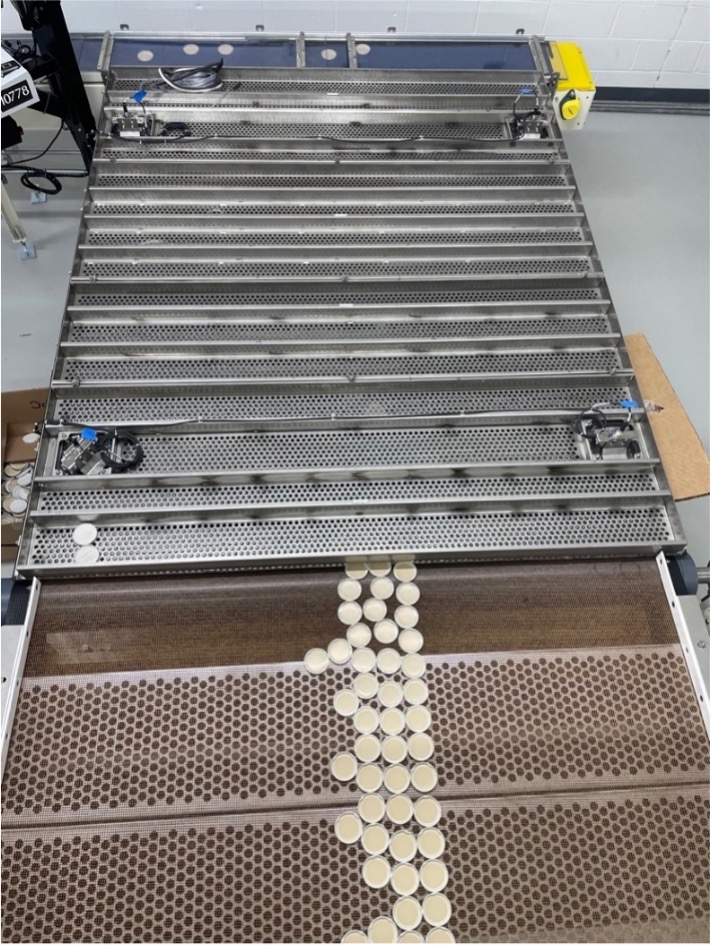

10. Lids exit the oven and start their cooldown process before heading to the light camera inspection system

11. The lids pass through the light camera system to inspect the quality

12. After the lids are inspected, they are transferred to the hopper for accumulation before being transferred to the conversion press

13. The Lids are transferred from the hopper via a conveyor belt and delivered to the conversion press where the software designed, EEASY Lid technology is stamped onto the lid

14. The lids are then inspected one last time before being placed into boxes to be shipped to a filler or manufacturer near you

Each step of this manufacturing process is integral to executing the innovative design of the EEASY Lid, which is based on eight years of research and development. Each EEASY Lid that comes off our production line is manufactured to be sustainable and durable (made of 100% aluminum), inclusive (easy-to-open for people of all ages and abilities) and safe (tamper evident cues).

We take pride in producing a premium jar lid that fills a critical gap in the packaging market. We hope you enjoyed a behind the scenes look at where the EEASY Lid is produced and be sure to ask manufacturers for the EEASY Lid on your favorite jarred food products.